When it comes to labeling options for products, businesses have a wide range of choices to consider. From traditional paper labels to more modern options like thermal direct film labels, each type of label offers its own set of benefits and drawbacks. In this blog, we will be discussing the advantages and disadvantages of thermal direct film labels compared to other labeling options on the market.

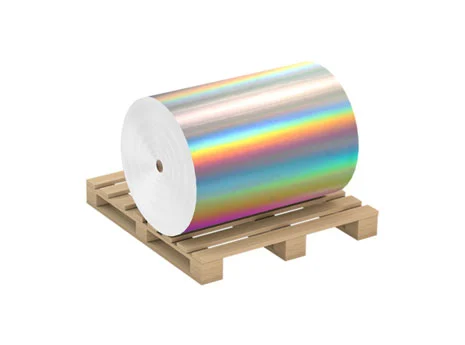

Thermal direct film labels have gained popularity in recent years for their durability and versatility. Unlike other types of labels that require ribbons or inks to print, thermal direct film labels use a special coating that darkens when exposed to heat. This not only makes them eco-friendly, as they do not require any additional materials for printing, but also results in a high-quality, smudge-resistant label that is perfect for products that may come into contact with moisture or friction.

On the other hand, traditional paper labels may fade or smudge over time, especially when exposed to harsh environments. Additionally, paper labels are more prone to tearing or peeling, which can make them less durable for long-term use. This is where thermal direct film labels shine, as they are made from a strong, tear-resistant material that can withstand the rigors of shipping and handling.

Another key benefit of thermal direct film labels is their cost-efficiency. Since they do not require any additional materials for printing, businesses can save on the costs associated with ink cartridges or ribbons. This not only reduces overhead expenses, but also streamlines the labeling process, making it quicker and easier to print labels on demand.

In comparison, other types of labels such as thermal transfer labels may require additional printing supplies, which can add up over time. Thermal transfer labels also tend to be more complex to set up and use, requiring special equipment and maintenance to ensure proper printing. This can be a disadvantage for businesses looking for a simpler, more cost-effective labeling solution.

One of the key advantages of thermal direct film labels is their versatility and customization options. With thermal direct film labels, businesses can easily print high-quality labels in various shapes, sizes, and colors to suit their branding and design needs. This allows for greater flexibility in labeling products, whether it be for food packaging, shipping labels, or product stickers.

In contrast, other labeling options such as pre-printed labels may limit businesses to a set design or size, which can be restrictive for companies looking to stand out in a competitive market. Thermal direct film labels offer the flexibility and customization options needed to create unique and eye-catching labels that help products stand out on store shelves.

In conclusion, thermal direct film labels offer a cost-effective, durable, and versatile labeling solution for businesses looking to streamline their labeling process and create high-quality, professional labels. By comparing thermal direct film labels with other types of labeling options on the market, businesses can make an informed decision on the best label for their products and brand.

English

English  中文

中文  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  Polska

Polska  Indonesia

Indonesia