Die-cutting of self-adhesive labels belongs to special die-cutting. Usually, after die-cutting, the unnecessary waste edges need to be removed, which is convenient for labeling. The irregular labels mentioned in the article refer to labels with irregular shapes. The difficulty of die-cutting process lies in the waste removal process. In actual production, there are often some problems due to the irregular shapes of the waste. This article will introduce some common problems and solutions of die-cutting process for self-adhesive irregular labels.

Breakage of waste edges during die-cutting is a common problem in self-adhesive label die-cutting. Many factors can cause this issue. Common influencing factors include face material strength, waste edge width, die-cutting tools, waste edge tension, and irregular labels. Here we mainly discuss the causes and solutions of waste edge breakage caused by irregular labels.

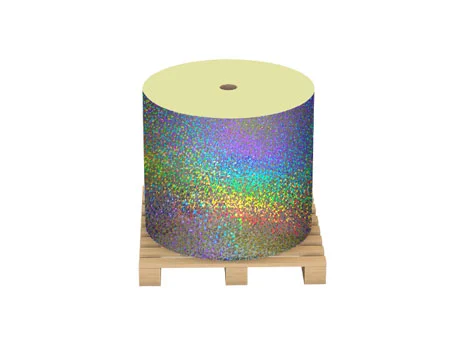

Causes of waste edge breakage: The special shape of irregular labels leads to irregular waste edges. When waste edges are removed, the diameter of the waste roller will be larger in areas with more waste edges, compared to areas with fewer waste edges. As a result, the tension of waste edges will be uneven, leading to easy breakage.

Solutions: (1) Add a balancing pressure roller on the waste roller to balance the diameter of the waste roll with external force. (2) Add appropriate backing paper to balance the tension of waste edges in positions where there is less waste. (3) Use pre-stripping process before die-cutting to reduce the release force of materials. The greater the release force, the greater the tension of waste removal, which is not conducive to smooth waste removal, especially for irregular labels. (4) Enhance the tensile strength of waste edges through processing techniques, increase the tensile strength of face material through surface lamination, and add a back knife device for die-cutting bottom paper at the die-cutting station, so that the waste edge becomes a double-layer structure of face paper and bottom paper, greatly enhancing its tensile strength.

Label curling is a common phenomenon in the die-cutting process of self-adhesive stock labels. It refers to the label being lifted from the bottom paper during waste removal, commonly known as "flying label". Curling is a prelude to flying labels, and common influencing factors include die-cutting quality, waste removal method, material release force, and ambient temperature.

Due to the special shape of irregular labels, during die-cutting waste removal, the edges of the labels are often lifted by waste edges and curled, making it impossible for labels to be properly wound and applied, resulting in high scrap rate. This phenomenon often occurs in areas with very small angles of label contours, such as the five points of a star-shaped label. During normal waste removal, the area is too small, resulting in relatively small release force, making it easy for the waste edge to lift and curl the label.

Solutions: As a trusted adhesive label manufacturer, we suggest when designing labels, try to avoid right angles or acute angles. The larger the angle, the more conducive to waste removal. To increase the waste removal angle, the waste roller can be modified into a steel ruler. Add foam pads to the label positions on the die-cutting plate. Install a sponge roller with a certain thickness on the label position of the thinner waste roller.

English

English  中文

中文  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  Polska

Polska  Indonesia

Indonesia