Special self-adhesive labels are a series of labels designed to meet the use environment, affixed storage environment, or apply special design. Today I will introduce to you several special self-adhesive labels.

1.Low temperature label

(1)Low temperature resistant label

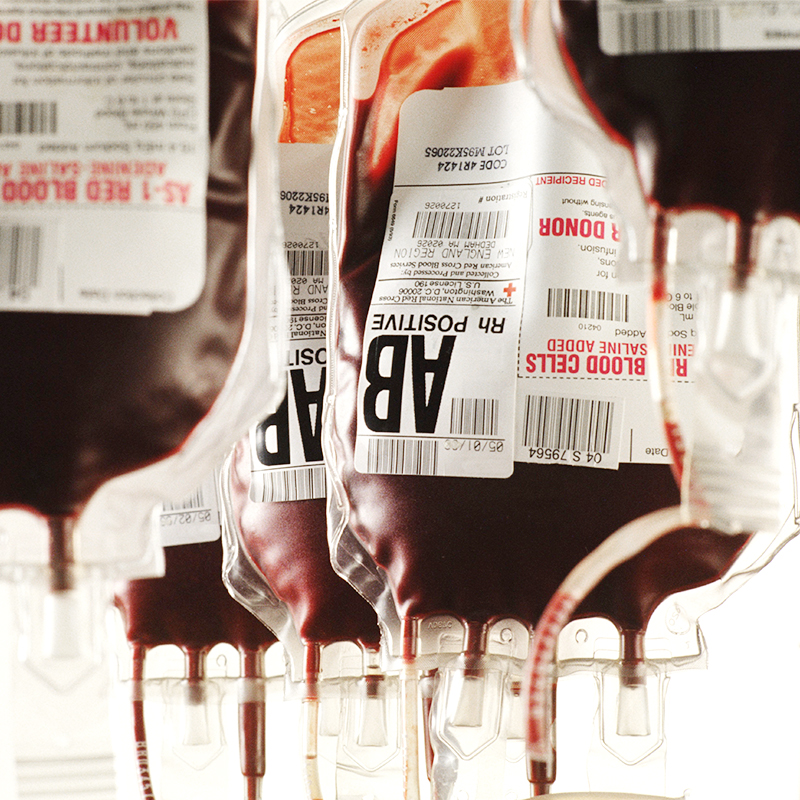

It is widely used in the pharmaceutical industry including test tube labels, blood bag labels, laboratory labels, etc., the food industry includes food bag labels and cold storage labels, etc., the industry includes outdoor equipment industrial laboratories, etc., and the chemical industry includes chemical laboratories and reagent labels, etc. Even -196°C (liquid nitrogen refrigeration) can ensure that the label will not be damaged in low-temperature environments.

• Adheres well to materials including polypropylene, glass, PVC and steel

• Supports multiple printing methods such as UV flexo, thermal transfer printing and UV inkjet printing

• A wide range of surface materials available, including clear and white films for different uses and temperatures

2.high temperature label

(1)tire label

Used for tire labels, the operating temperature of the label can reach up to 210°C, and can be vulcanized simultaneously with the tire. After vulcanization, the barcode and the tire are integrated and will never fall off. It can accompany the tire throughout its life cycle, does not deform or discolor, is waterproof, acid-resistant, alkali-resistant, salt-resistant, resistant to most petroleum oil stains, and low-fat solvents, wear-resistant, resistant to high and low temperatures, and can be used with most resin carbons bring.

(2)Fire retardant label

The surface material complies with UL94 VTM-0 and has excellent fire protection effect; it has excellent tear resistance, dimensional stability, chemical corrosion resistance and good electrical insulation, and is suitable for making various labels that require flame retardant properties. It can meet the fire protection requirements in the energy and chemical industry.

3. Anti-counterfeiting label

Fragile labels are an important type of self-adhesive labels. The breaking strength of the facestock is much lower than the bonding ability of the adhesive. It has the characteristics that it cannot be completely peeled off after pasting and cannot be reused. Fragile labels surface materials are processed by printing, die-cutting and other processes to make fragile labels or fragile stickers, also known as fragile product warranty stickers. It is mainly used for products that are difficult to accurately guarantee with regular warranty methods. Unconventional product identification methods.

(2)Color changing label

For example: anti-counterfeiting labels that turn red when exposed to water, also known as water-sensitive warning anti-counterfeiting self-adhesive labels or water-sensitive labels, waterproof labels, and water-changing labels. Turn red when exposed to water Label materials will change color when completely exposed to water, and the color is irreversible. Turning red when exposed to water is a warranty that currently provides maintenance services for mobile phones, batteries, electronics, appliances, LCDs and other products that are difficult to identify or misidentify or control after being damaged by water. At the same time, turning red when exposed to water is also a sign of water intrusion into ocean-going cargo. A new type of product developed to identify and provide legal basis for claims. The main function of the label that turns red when exposed to water is that when the base material is completely exposed to water, the surface will turn red when exposed to water and will turn into a color that is obviously different from the previous color and is irreversible.

English

English  中文

中文  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  Polska

Polska  Indonesia

Indonesia