Materials labeled underwent testing, validation, and adhered to the standards set by the pharmaceutical industry.

Ensure the safety of the label design and adhere to the standards set by GMP.

Technology is changing the way pharmaceutical labels are created, printed, and handled. With the emergence of digital printing, pharmaceutical labels can now be printed on demand, allowing for quick turnaround times and cost savings. Additionally, with the use of RFID tags and other sensors, pharmaceutical labels can now be tracked in real-time, providing better accuracy and safety for pharmaceuticals. Furthermore, digital printing allows for the use of variable data printing, which means that unique identifiers can be printed on a single label, enabling traceability and making counterfeiting more difficult. Finally, technology is helping to reduce waste. By using digital printing, digital label for pharmaceutical can be printed on demand, eliminating the need for excess inventory and saving companies both time and money.

Durability: Because pharmaceutical labels contain important information for the consumer, it is crucial that the label remains in place and legible at all times.

Material: Use renewable materials to prevent product contamination.

Quality Assurance: There is a strong QC team implementing quality control measures.

Pharmaceutical Label Printing Capabilities: We offer the following label printing capabilities: Digital label printing; Flexographic printing.

Pharmaceutical labels are an important tool in helping to ensure patient safety. The digital label for pharmaceutical provides key information about the medication, such as the dosage, side effects, and potential interactions with other drugs. This information is essential for medical professionals to ensure that the correct medication is being prescribed and that the patient is taking the correct dosage. Additionally, pharmaceutical labels can help to reduce potential errors by making sure the correct medications are being prescribed and that the patient is taking the correct dosage. They can also help to alert medical professionals to potential drug interactions. By providing this vital information, pharmaceutical labels can help to improve patient safety by reducing the risk of adverse events caused by medication errors.

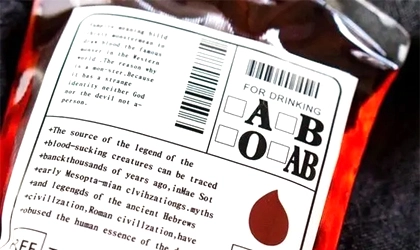

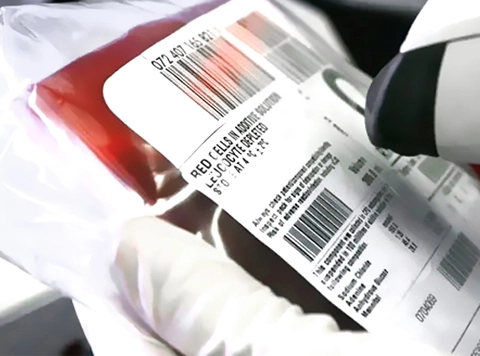

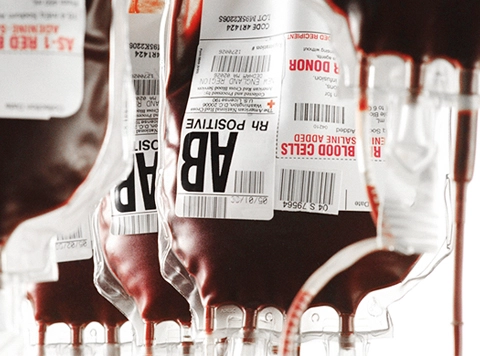

Blood bags

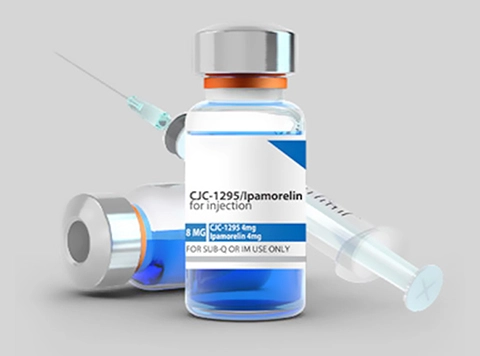

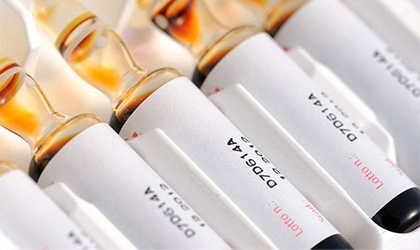

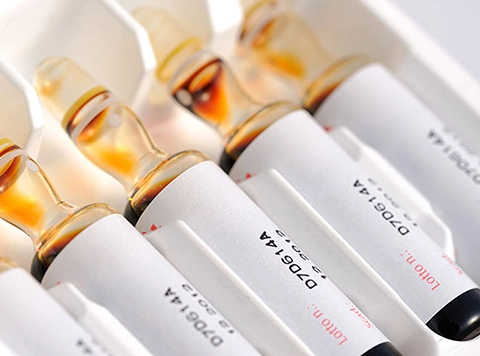

Pharmaceutical Bottles

Cardboard boxes

Sterilization pouches

Syringes

Customization can be made to suit your requirements

Shield the medication

Avoid altering the materials of the product or packaging

Avoid adding harmful substances to the medication

Align with the medication

Ensure efficient functioning and performance

Assured secure delivery of medication

Adopting a robust labeling process: Companies should develop and implement a labeling process that is consistent and thorough, ensuring that every label has the required information and is up-to-date.

Regularly review and update labels: Companies should regularly review and update their labels to ensure accuracy and compliance with relevant regulations.

Leverage technology: Companies should utilize modern technologies such as bar coding, RFID tags, and digital printing to improve the accuracy and speed of the labeling process.