Piggyback labels are a unique type of labeling solution that are characterized by their multi-layer structure. This structure is designed to provide a versatile and flexible labeling solution that can be customized to meet a variety of needs. The top layer of these labels can be made from a range of materials, including paper, metallic paper, and film. This allows for a wide range of aesthetic options, from simple and understated to bold and eye-catching.

The middle layer of piggyback labels can also be made from a variety of materials, including paper, white film, or transparent film. This layer is designed to serve functional applications, providing a sturdy and durable base for the top layer. The choice of material for this layer can be tailored to the specific needs of the application, whether it requires a high level of durability, a certain level of transparency, or a particular aesthetic appeal.

One of the key features of piggyback labels is that we can design the top label to be either stickable or non-sticky after it is peeled off. This provides a high level of flexibility, allowing the labels to be used in a variety of different ways. For example, a stickable top label could be used to reseal a package after it has been opened, while a non-sticky label could be used for informational purposes.

Piggyback labels are commonly used in a number of different areas. They are particularly popular in logistics, where they can be used to track and manage inventory. They are also frequently used as promotional price tags, providing a convenient and effective way to display pricing information. In addition, they are often used in the pharmaceutical industry, where they can provide important information about medications. These are just a few examples of the many potential applications for piggyback labels.

We are proud to announce that we have successfully developed a unique, strongly sticking special adhesive specifically designed for tire adhesive labels. This innovative product has been meticulously engineered to securely adhere to highly grooved rubber surfaces, ensuring a firm and lasting bond even in the most challenging conditions.

Jinya special adhesive is not just about sticking power, it also offers protection. It is designed to work in harmony with long-lasting paper label faces and paper/aluminium laminate, providing an additional layer of protection to the tire. This ensures that the label remains intact and legible, even after prolonged exposure to harsh environmental conditions, rough handling, or extended periods of storage.

As a leading label stock manufacturer, our special adhesive has been developed with excellent printability in mind. The paper/aluminium laminate it is designed to work with offers superior print quality, ensuring that the labels remain clear and readable throughout their lifespan. This is a crucial feature, as it ensures that important information about the tire, such as its size, type, and manufacturing date, remains visible and accessible throughout the supply chain.

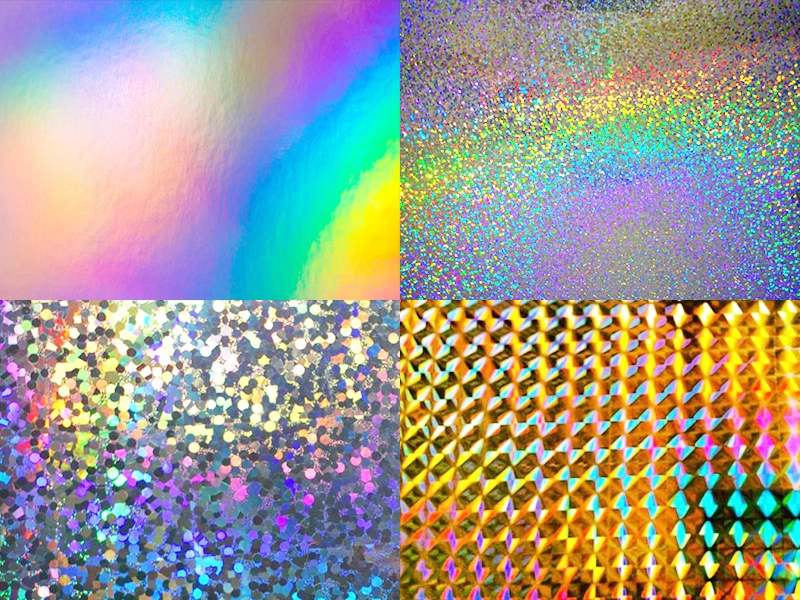

The use of premium polyester and polypropylene laminated to custom holographic labels has revolutionized the packaging industry, making it easier to convert packaging for a variety of uses. These materials are particularly beneficial for promotional, gift, spirits, cosmetics, and home care product labels. The high-quality polyester and polypropylene used in these labels ensure durability and longevity, making them a reliable choice for businesses across various sectors.

The holographic labels, customized to the specific needs of the product, add a unique and eye-catching element to the packaging. This not only enhances the aesthetic appeal of the product but also serves as an effective marketing tool, attracting potential customers and boosting sales. Jinya also offers a range of cost-effective polypropylene options for food promotion and decorative labels. These labels are designed to withstand the rigors of food packaging, ensuring that they remain intact and visible even in challenging conditions. They are also perfect for adding a decorative touch to your products, making them stand out on the shelves and attracting the attention of consumers.

Jinya polypropylene labels are not only cost-effective but also versatile, making them suitable for a wide range of applications. Whether you need labels for food promotion or decorative purposes, our polypropylene labels are the perfect solution.

Inkjet color printers are becoming increasingly prevalent in today’s fast-paced digital world, particularly for on-demand printing needs. This is largely due to their ability to produce high-quality prints with vibrant colors and sharp details. As the demand for these printers grows, so does the need for compatible materials that can effectively work with them.

Jinya, a leading supplier of printing solutions, has stepped up to meet this demand by offering a wide range of materials that are compatible with both dye ink and pigment ink inkjet printers. These materials have been carefully selected and tested to ensure they deliver the best possible results when used with these types of printers. We also offer a variety of options to cater to different application needs. This includes paper and film labels, which are available in both matte and high gloss finishes. The matte finish is ideal for those who prefer a more subtle and professional look, while the high gloss finish is perfect for those who want their prints to stand out and make a bold statement.

All labels from Jinya are designed to be durable and resistant to smudging, ensuring that your prints remain clear and vibrant for a long time.

The garment label materials made by Jinya boast remarkable qualities, including exceptional initial tack and an impressive resistance to yellowing, making them an ideal choice for a wide range of substrates. These materials have proven to be highly suitable for creating garment labels using various fibers, such as silk, wool, polyester, and even delicate fabrics like lace. Additionally, they exhibit excellent performance on medium density fabrics, ensuring a secure and long-lasting bond. Moreover, these materials have been specifically formulated to cater to the needs of light dyed cotton fabrics, guaranteeing that the labels remain vibrant and intact. However, to ensure the utmost precision and reliability, it is strongly advised to conduct rigorous tests on the corresponding substrates, particularly those that are closely related to the fabrics being utilized. By subjecting the materials to comprehensive testing, including stress and durability assessments, you can confidently ascertain their compatibility and suitability for your specific garment labeling requirements.