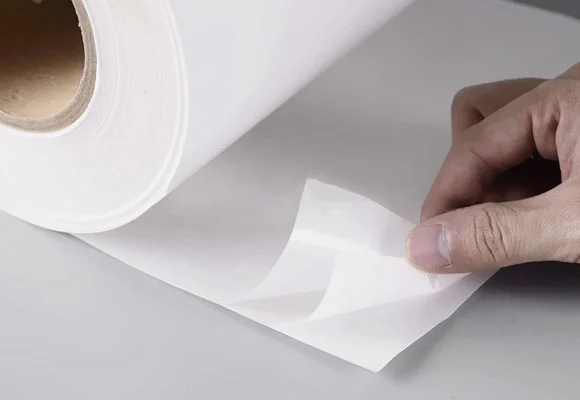

SDB8022 is a coated paper sticker with excellent printing quality and strong adhesion. These stickers are suitable for different applications, including product labeling, inventory management, and shipping. They are highly reliable and durable.

| weight | thickness | material | |

| Face Material | 80±10%g/m2 ISO 536 | 0.072±10%mm ISO 534 | Specially treated high semi gloss white coated paper |

| Liner | 58±10%g/m2 ISO 536 | 0.055±10%mm ISO 534 | Super calendered double layer semi-gloss white glassine backing |

| Adhesive | A general permanent rubber adhesive. HH is an adhesive with a high initial viscosity. It has excellent performance on many packaging materials. It can be used for non-direct contact labeling of products such as food, medicine and cosmetics. | ||

| Peel adhesion | initial adhesion 14 N/25mm FTM 9 st.st | 20 minutes Peel adhesion value on steel at 180 angle 18N/25mm FTM 1st.st | 20 minutes Peel adhesion value on steel at 90angle 9 N/25mm FTM 2st.st |

| Temperature | Min. Appl. Temp. -5 ºC | Service Temp. -10ºC±65ºC (24H after labeling) | |

Widely used in semi-gloss color label printing for promotional and industrial purposes. Common uses include labeling for cosmetics, medications, and industrial products. Most substrates, like cardboard and plastic film, have flat, conventional surfaces that can accommodate this product's attachment. The use of this material on PVC substrates is not recommended. The aforementioned recommendation, illustration, and explanation are not meant to serve as Jinya's warranty. To verify compliance with the requirements of the use of environment, all sales of Jinya coated paper label products must be tested by the customer in the intended environment.

The advantages of coated sticker paper include water resistance, durability, and smudge resistance. The ink and toner adhere better to coated sticker paper, providing a more vibrant and high-quality image. Coated paper is also more durable, allowing it to withstand exposure to moisture, light, and other environmental factors without becoming damaged or faded.

Shelf life

12 months, applicable only to the material delivered by Jinya which has not undergone further processing, under the following STORAGE CONDITIONS:

This material must be stored at a temperature of 23±2ºC and 50±5% of Relative Humidity.

Storage area must be dry and clean.

Keep the material in the original packaging when not used in order to protect it from dust and contamination.

Do not expose to direct sunlight or heat sources.

English

English  中文

中文  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  Polska

Polska  Indonesia

Indonesia