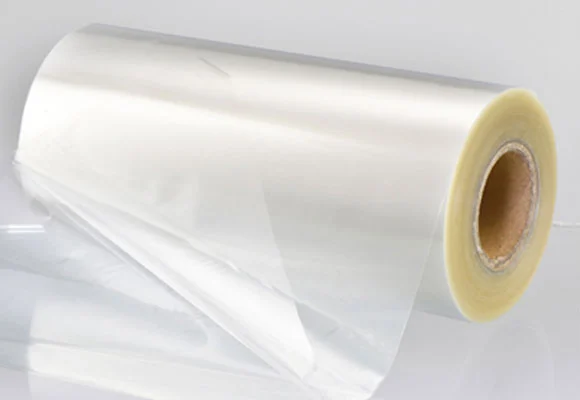

Using clear BOPP material, the Clear Bopp Label BFR5030 is a premium label. It is appropriate for use with a number of printing techniques and is perfect for a number of purposes.

| weight | thickness | material | |

| Face Material | 67±10%g/m2 ISO 536 | 0.05±10%mm ISO 534 | Biaxially oriented transparent polypropylene film with special coating on the surface |

| Liner | 42±10%g/m2 ISO 536 | 0.03±10%mm ISO 534 | Biaxially oriented transparent polyester release film |

| Adhesive | Water removable, acrylic based adhesive. This is a removable adhesive. It has proper initial tack and high resilience. It is designed for recycling applications where the label has to be removed in warm alkaline water. It can be torn and pasted repeatedly on many non-paper substrates without leaving any glue residue. | ||

| Peel adhesion | initial adhesion 7N/25mm FTM 9 st.st | 20 minutes Peel adhesion value on steel at 180° 6N/25mm FTM 1 st.st | 20 minutes Peel adhesion value on steel at 90° 4N/25mm or tear off FTM 2 st.st |

| Temperature | Min. Appl. Temp. 10ºC | Service Temp.-10ºC±40ºC (24H after labeling) | |

The material has certain tear resistance and chemical corrosion resistance, stable physical and chemical properties, good anti-fouling, oil-proof, good transparency, and has a certain barrier performance. It can be repeatedly pasted on many objects. Excellent washing and removal performance, widely used to make beer bottle labels, etc. Due to the different surface properties of the object to be attached. It is recommended to carry out the label sticking test on the object to be put into use.

The above suggestion, application, and elaboration are not intended as the guarantee of Jinya. All sales of Jinya products shall be tested by customer in the final environment to confirm compliance with the requirements of the use of environment.

Corona is required before printing, suitable for most printing methods and inks. It is necessary to test the ink before printing. Note that the temperature during the drying process of the ink should not be higher than 45°C to prevent the reversible curling of the surface material. It is suitable for high-speed overprinting, die-cutting and waste discharge on a rotary machine. Due to the thin substrate, a very sharp die cutter should be used. Excessive tension should be avoided, causing the adhesive to overflow. Static electricity must be prevented or a static elimination device installed on the processing equipment.

Water wash removal test

Take a sample of 50mm*100mm, paste it on the surface of an ordinary beer glass bottle, place it at room temperature for more than 12H, then soak it in 80-90°C hot water, the label will completely fall off within 60-120S and no adhesive will remain on the bottle.

Shelf life

12 months, applicable only to the material delivered by Jinya which has not undergone further processing, under the following STORAGE CONDITIONS:

This material must be stored at a temperature of 23±2ºC and 50±5% of Relative Humidity.

Storage area must be dry and clean.

Keep the material in the original packaging when not used in order to protect it from dust and contamination.

Do not expose to direct sunlight or heat sources.

English

English  中文

中文  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  Polska

Polska  Indonesia

Indonesia