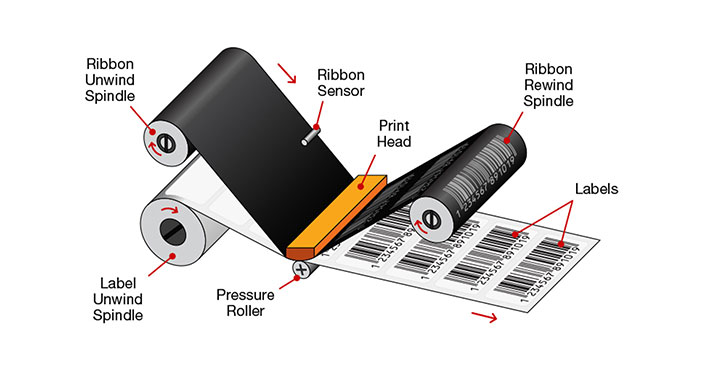

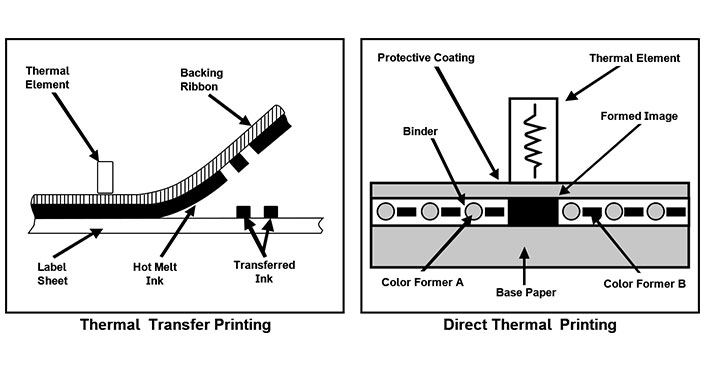

Direct thermal printers print by applying heat to the material. It doesn't require any ribbon, ink, or toner, but it has a heat-sensitive coating that reacts and turns black when heat is applied. Thermal transfer printer has the same printhead as direct thermal, but it requires ribboon to work with the paper. When heat is applied, the ribbon will be transferred to the paper. Since the feature of direct thermal printing, it can fade and the labels can become difficult to read and scan over time. Normally we suggest to choose direct thermal for applications that require a label duration of less than six months, such as shipping labels, receipts, tickets, and labels for perishable goods. Thermal transfer printing is ideal for long-term applications in which the printing media will be used for more than six months or will be exposed to harsh conditions.

Direct thermal labels have a short shelf life due to the usage of heat-sensitive materials; they typically only last six to eight months. They are prone to being readily scratched, and prolonged exposure to intense sunshine or high temperatures will hasten the fading of the print.

Direct Thermal papers are mainly used in the logistics, retail and food end-use areas. Jinya offers solution for the challenging conditions with the possibility to add variable information, such as cold chain, express company, and linerless labelling.

Coating is the key point of thermal labels. Our thermal labels are divided into two types, one is eco thermal label and the other is TOP thermal label. Depending on the application, the protective coating of thermal paper is more functional. In the demanding environments, Jinya has different functional facestock to meet the application requirements, such as waterproof, oil-proof, scratch-proof, plastic-proof and alcohol-proof.